As the largest perforating company in the world, RMIG has over a century’s experience in the perforation industry. This impressive size and experience means RMIG has a local presence in a range of markets, providing accessible contacts for customers no matter what their query.

RMIG is dedicated to being an innovative and reliable solution provider in the perforation industry, as well as being recognised as a benchmark for customer service and optimised logistics.

RMIG is dedicated to being an innovative and reliable solution provider in the perforation industry, as well as being recognised as a benchmark for customer service and optimised logistics.

RMIG’s perforated sheets can be used effectively within a number of areas, and RMIG has six dedicated market sectors covering Industrial Processing, Food Processing, Buildings and Interiors, Multimedia and Communication, Automotive, and Household Appliances.

One particular area of Industrial Processing is medical and pharmaceutical, where RMIG’s perforated materials are able to give firm tolerances during their manufacture, and are well suited for use in sterile environments. RMIG’s perforated products also have numerous uses in the petrochemical sector, from industry specific applications such as filtration, to oil and gas exploration, as well as more general applications such as walkways in processing plants.

Additionally, RMIG works with biomass drying applications. The demand for alternative sources of sustainable and renewable energy is always growing. RMIG’s Bridge Slot sheets are the most effective way of drying woodchip to an optimum moisture content, ensuring boilers operate efficiently to benefit farming and agriculture.

Additionally, RMIG works with biomass drying applications. The demand for alternative sources of sustainable and renewable energy is always growing. RMIG’s Bridge Slot sheets are the most effective way of drying woodchip to an optimum moisture content, ensuring boilers operate efficiently to benefit farming and agriculture.

The RMIG Bridge Slot sheets play an essential role when it comes to the design and manufacture of biomass drying floors. The combination of sheet thickness and opening size allows RMIG’s sheets to be used either as a suspended floor in wood chip drying containers and trailers, or as drive-on drying floors in outdoor buildings. The bridge slot opening size determines the products that can be dried, which range from fine oilseed rape through to larger grains and cereals, as well as logs and wood chip drying.

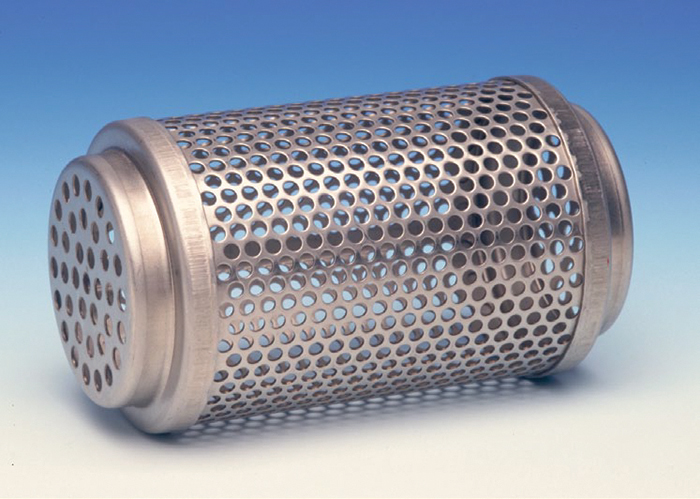

In the production of perforated dishwasher filters, RMIG offers the complete service from perforating and forming, including surface treatment, right up to final assembly complete with plastic rings and funnels. RMIG also has decades of experience in the manufacture of perforated sieves using highly developed technical methods and strict quality control systems to guarantee customers are receiving the best possible product.

T +44 1925 839610

info.uk@rmig.com

www.rmig.com/en