In this issue of Industrial Solutions, we are delighted to announce UNISIG as our Automation Company of the Year.

The UNISIG team will be revealing its innovative, intuitive machinery capability exclusively at EMO Hannover 2023: the world’s leading trade fair for production technology from the 18th-23rd September.

The UNISIG team will be revealing its innovative, intuitive machinery capability exclusively at EMO Hannover 2023: the world’s leading trade fair for production technology from the 18th-23rd September.

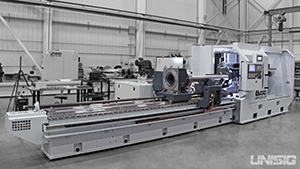

UNISIG is a market-leading American producer of deep hole drilling machines, supplying to smaller bespoke companies and large original equipment manufacturers (OEM). As leading global experts, UNISIG has the expertise and pedigree to provide advanced precision-driven machinery for all jobs, with its complete deep hole drilling solution from machinery, tools to automation.

The American Powerhouse was established in 1981 and since that time, has built up an unparalleled position across the global industry, with its renowned production of gun drilling and deep hole drilling machines. Entrust Manufacturing Technologies acquired the company in 1995 and moved to the state-of-the-art Milwaukee, USA headquarters.

The American Powerhouse was established in 1981 and since that time, has built up an unparalleled position across the global industry, with its renowned production of gun drilling and deep hole drilling machines. Entrust Manufacturing Technologies acquired the company in 1995 and moved to the state-of-the-art Milwaukee, USA headquarters.

Now with a strong customer base across various sectors including: aerospace, automotive, energy, firearms, hydraulic cylinders, military and medical sectors, UNISIG has market-leading installation capabilities across Europe, Asia and America.

With world-class design engineers on board, UNISIG has the in-built expertise to design and perfect machinery for other deep hole procedures such as: BTA, gun drilling, counterboring/reaming, pull boring, trepanning, skiving and roller burnishing, bottle boring, bottom forming and many more.

The high-powered B-series from UNISIG has transformed BTA drilling (Boring and Trepanning Association, facilitating precision drilling of 25mm to 500mm, up to 20m deep, ideal for all BTA drilling applications.

For rigid, deep hole drilling, the larger swing B-series has minimized backlash a more powerful drive, with state-of-the-art smart controls, giving high usability with unlimited capability.

For rigid, deep hole drilling, the larger swing B-series has minimized backlash a more powerful drive, with state-of-the-art smart controls, giving high usability with unlimited capability.

For example, the UNISIG B600 can drill 6” diameter holes up to 32 feet deep, with flawless accuracy and concentricity due to the use of counter-rotation of the workpiece. The B600 can perform secondary machining capabilities such as skiving, stepped bores or internal shapes up to 8” in diameter. This cutting-edge machine is perfectly placed for deep hole drilling for aerospace component manufacturers.

From deep to miniature, another groundbreaking machine is the UNX-CP – precision-designed for off-centre holes, with greater depth to diameter ratios. The winning Cartesian and Polar positioning (CP) combination works in tandem with motion control to allow meticulous precision in small diameter deep hole drilling, for ultimate accuracy. With programmable, off-centre counter-rotation, hole concentricity is enhanced, even at depth to diameter ratios of 375:1.

We caught up Philipp Steimle: Sales and Service manager for Europe to find out more about the latest developments, “Our company is expanding its own manufacturing department, due to ongoing supply issues. The recently installed Kellenberger CNC grinding machine will allow us to finish all the drilling spindles in-house. We have also recently installed a laser-cutting machine, a CNC press brake and welding stations, so that we can do all the guarding and coolant reservoirs in-house to avoid delays in our machine building.”

We caught up Philipp Steimle: Sales and Service manager for Europe to find out more about the latest developments, “Our company is expanding its own manufacturing department, due to ongoing supply issues. The recently installed Kellenberger CNC grinding machine will allow us to finish all the drilling spindles in-house. We have also recently installed a laser-cutting machine, a CNC press brake and welding stations, so that we can do all the guarding and coolant reservoirs in-house to avoid delays in our machine building.”

“The UNE6 series for medical instrument drilling with its fully integrated automation is a game changer for the industry and proving highly popular in the market. We have invested in more in-house production rather than external third parties, to keep on top of our orders.”

The Milwaukee facility at the global UNISIG headquarters was expanded by over 100,000 sq.ft. in 2019, to keep in line with expanding production levels. The further addition of the CNC grinding machine will also help generate greater production, alongside timely upgrading across the production facility. For bespoke custom-built drilling machine orders, the in-house design engineers at the UNISIG Tech Centre in Milwaukee are well versed in the process of prototype building, due to its market-leading reputation.

UNISIG prides itself on rapid machinery and part shipping orders around the world, alongside a comprehensive routine servicing and repair service offered remotely and on-site. Furthermore, installation can be carried out expertly by proficient in-house engineers across the world, on demand. Customers can view the full machinery range, with specification capacity (including hole depth in mm) on the UNISIG website.

UNISIG prides itself on rapid machinery and part shipping orders around the world, alongside a comprehensive routine servicing and repair service offered remotely and on-site. Furthermore, installation can be carried out expertly by proficient in-house engineers across the world, on demand. Customers can view the full machinery range, with specification capacity (including hole depth in mm) on the UNISIG website.

Industrial Solutions cannot praise UNISIG enough for its outstanding commitment to the industry, from industry-leading machines to exceptional customer service.

The UNISIG team will be showcasing its innovative machinery capability at EMO Hannover 2023: the world’s leading trade fair for production technology from the 18th-23rd September.

The team will be happy to answer enquiries from across all sectors.

For more information on UNISIG, please see the website below:

www.unisig.com