In this issue of Industrial Solutions, we are delighted to select UNISIG for our Machinery Excellence Award.

UNISIG is an industry-leading American producer of deep hole drilling machines, supplying to customers across aerospace, automotive, energy, firearms, hydraulic cylinders, military and medical sectors, from smaller bespoke companies, to large original equipment manufacturers (OEM.)

UNISIG is an industry-leading American producer of deep hole drilling machines, supplying to customers across aerospace, automotive, energy, firearms, hydraulic cylinders, military and medical sectors, from smaller bespoke companies, to large original equipment manufacturers (OEM.)

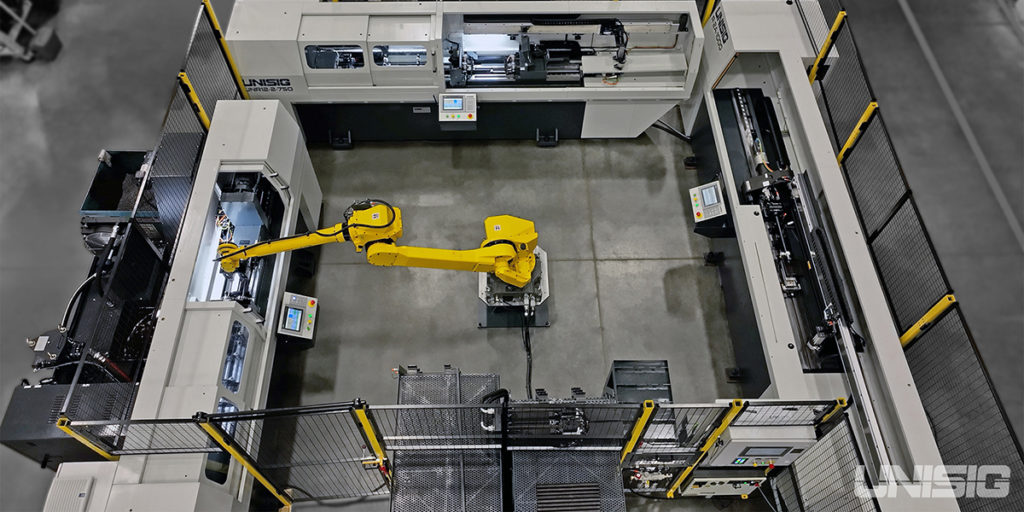

With unapparelled installation capabilities across Europe, Asia and America, UNISIG has the expertise to provide advanced precision-driven machinery for all jobs, with its complete deep hole drilling solution from machinery, tools to automation.

The American heavyweight was established in 1981 and since that time, has built up pole position across the global industry, with its renowned production of gun drilling and deep hole drilling machines. Entrust Manufacturing Technologies acquired the company in 1995 and the company moved to the purpose-built Milwaukee, USA headquarters.

The drilling capabilities include: gun drilling, BTA, counterboring/reaming, trepanning, pull boring, skiving and roller burnishing, bottom forming, bottle boring and much more. With a wide range of stock machinery lines for diverse manufacturing needs, UNISIG is happy to provide bespoke-engineered machinery across all applications.

The drilling capabilities include: gun drilling, BTA, counterboring/reaming, trepanning, pull boring, skiving and roller burnishing, bottom forming, bottle boring and much more. With a wide range of stock machinery lines for diverse manufacturing needs, UNISIG is happy to provide bespoke-engineered machinery across all applications.

The US Milwaukee facility at the global UNISIG headquarters was expanded by over 100,000 sq. ft. in 2019, to keep up with increased production capacity demand levels. The CNC grinding machine also supports greater production, alongside regular upgrading across the production facility. The dedicated design engineers at the UNISIG Tech Centre in Milwaukee are more than happy to build customised drilling machine orders, from prototypes to finished machines.

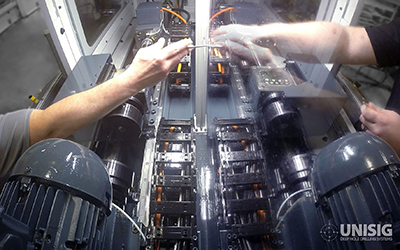

We spoke to Philipp Steimle: Sales and Service manager for Europe to ask more about company developments, “Our company is expanding its own manufacturing department, due to ongoing supply issues. The recently installed Kellenberger CNC grinding machine will allow us to finish all the drilling spindles in-house. We have also recently installed a laser-cutting machine, a CNC press brake and welding stations, so that we can do all the guarding and coolant reservoirs in-house to avoid delays in our machine building.”

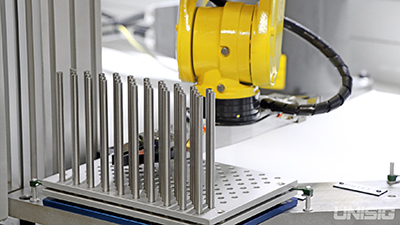

“The UNE6 series for medical instrument drilling with its fully integrated automation is a game changer for the industry and proving highly popular in the market. We have invested in more in-house production rather than external third parties, to keep on top of our orders.”

“The UNE6 series for medical instrument drilling with its fully integrated automation is a game changer for the industry and proving highly popular in the market. We have invested in more in-house production rather than external third parties, to keep on top of our orders.”

One of the aspects that stands UNISIG apart is its commitment to excellence with customer service: from quick machinery and part shipping orders delivered around the world, to meticulous service and repair jobs (conducted on-site and remotely) and expert installation by UNISIG engineers.

The recent addition of two new SSI Schaefer LOGIMAT® vertical lift modules (VLM) in the parts warehouse have further enhanced the already-excellent customer service. The storage units hold up to 28 tons of spare parts each, providing welcomed streamlined organisation and tracking. UNISIG operators can now effortlessly access parts inventory on the touchscreen and the VLM moves the correct tray forward, whilst a laser then selects the precise bin and location of the required part. This use of automated technology has optimised the inventory storage capacity and created a smoother, more accurate retrieval system.

UNISIG leads the way in expertly engineered, high-performance gundrilling, such as the Dual-Spindle gundrilling machine with counter-rotation (UNE12-2-750-CR). This has impressive features, for example, the two spindles offer advanced-precision gundrilling to 12mm in diameter and 750mm in depth, at 12,000rpm. That’s not all. The machine has over 2,000psi coolant pressure, with integrated chip collection system and touchscreen control panel. The characteristic counter-rotation of cylindrical workpieces provides next-level hole straightness.

Contact UNISIG to discuss how deep hole drilling equipment would support your business venture today:

www.unisig.com