Founded in 1981, UNISIG is a dedicated provider of high quality deep hole drilling systems. Over the decades since its establishment the company has progressed in leaps and bounds to become an internationally recognised high performance machinery manufacturer.

The reputable brand is widely acknowledged and continually praised for its suite of contemporary solutions and has become a prominent supplier in its niche industry. Its history is relatively diverse; in its early days UNISIG was principally concerned with the production of deep hole drilling equipment and the sales and servicing of VDF machine tools, whilst it is now a forward-thinking enterprise boasting a wide range of quality accessories, automation and tooling.

In 1995 Entrust Manufacturing acquired the business in a strategic move that propelled UNISIG to even greater heights. Associating with this esteemed contract manufacturing service provider encouraged the organisation to expand further and – as a result – relocate to its current headquarters in Wisconsin in the USA. From this modern facility the team can ably deliver suitable technologies and solutions to its ever-increasing customer base, prompting work process optimisation in a number of important applications.

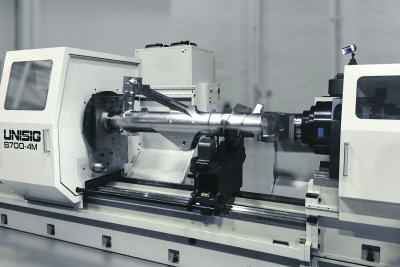

The UNISIG offering comprises independently tried and tested products in the form of (for example) BTA, gundrilling, trepanning and skiving machines that have been meticulously developed in order to align with the necessary demands set by the industry (namely, where applicable, ISO, DIN and IEC). The dependable products are made with care and attention to detail in production plants situated in America and Germany where they are then dispatched – for customer convenience – with the obligatory durable tooling and machine accessories.

Philipp Steimle, Managing Director of UNISIG’s European Sales Department, was keen to discuss the popularity of the company’s solutions in further detail: “Our machines are designed with purpose for a full range of deep hole drilling applications and have proven useful within a range of industries such as the aerospace, automotive, energy and medical markets,” he enthused.

“They are developed based on years of experience with drilling applications, customer challenges and production environments. As an innovative organisation we are continuously upgrading our range in order to offer the most up-to-date technology to our customers and we are wholly committed to continuously improving our business through investment, the use of technology and promoting a highly trained workforce.”

The UNISIG B700 Drop Bed Machine acts as a perfect illustration of this quest for ongoing innovation. This product, which is the latest release to enhance the company’s comprehensive range, is a new drilling system that gives an advantageous lift to Aerospace Landing Gear Production. This original product was devised to generate high-precision features on irregularly shaped aerospace components – such as landing gear struts – and has helped make significant improvements within the field as a more flexible prototype with a lighter structure.

This particular product is advantageous in the respect that it is incredibly flexible with an ability to process medium sized, uniform-shaped workpieces with minimal changeover time from one to another. The component is the latest variation from UNISIG’s extensive B-series line, which was strategically adapted for the on-center drilling of cylindrical workpieces in applications such as aerospace, defense and oil & gas.

As well as being equipped to conduct standard BTA drilling methods, these first class machines are also capable of counterboring, trepanning and skiving and roller burnishing processes, achieving the extremely strict tolerances required by manufacturers in the aforementioned (and other) industries. Another significant advantage to note is the great usability of the systems; they are markedly easier to operate than the more generic prototypes, which, in their conventional form, are known as being unhelpfully cumbersome and clunky.

The UNSIG team isn’t just concerned with the simple provision of cost-effective and fully functional products, however. The experienced pool of staff members also offer customers support in a highly useful, consultative manner. This extends to (where required) the training of individuals who may not be aware of how to operate such equipment and application assistance for the accomplishment of singular production goals.

If you are interested in enquiring about any of the mentioned services or solutions then please don’t hesitate to contact UNSIG at your earliest opportunity; the team of friendly and informed representatives will be more than happy to assist you should you have any particular enquiries or requests. Contactable via telephone or email, you can receive the answers you require to any questions posed, and any further information can be gleaned from the company website (see below) or on the dedicated UNISIG Twitter page.

T +44 (0)7125 9687590

Twitter: @UNISIG